Stratasys’ AIS package, announced in 2017 alongside the news of its partnership with Boom Supersonic, aims to improve the mechanical properties of 3D printed aircraft production through repeatable development. Streamlining the qualification process for 3D printing in aerospace Jagemann added, “During the first three years of our partnership, we 3D printed more than 200 parts for tooling, prototypes and test benches using Stratasys’ F370 and Fortus 450mc 3D printers, and have saved hundreds of hours of work time, enabling rapid iteration of design cycles.” The F900 3D printer from Stratasys.

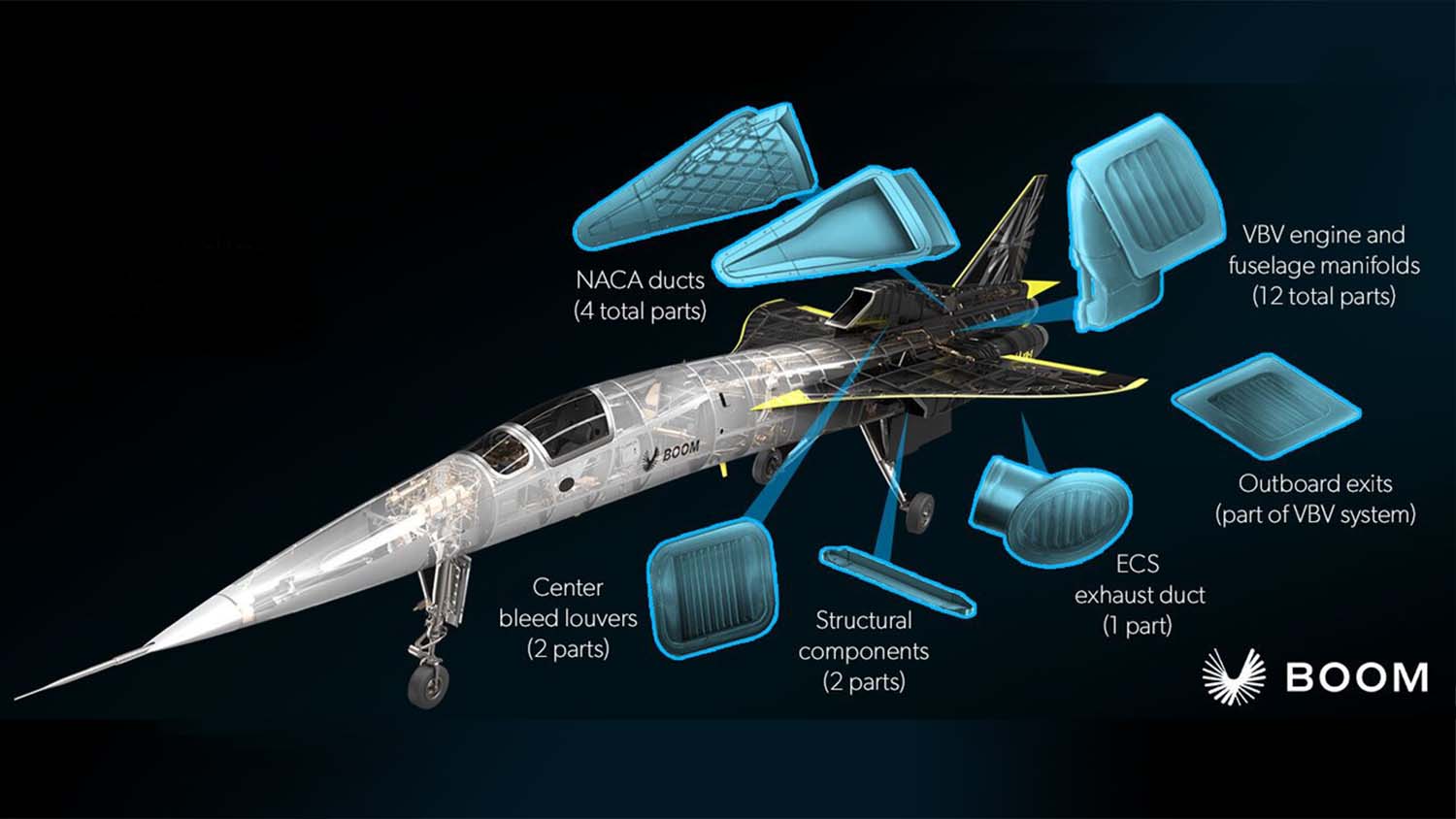

Using the Stratasys F900 3D printer with the AIS package, the company is reported to have already produced hundreds of 3D printed parts for the demonstrator aircraft. The new agreement between the companies moves beyond rapid prototyping however, with Boom Supersonic aiming to integrate Stratasys’ FDM 3D printing technology into flight part production for the XB-1 and eventually the Overture. Boom Supersonic opted to use the Stratasys F370 and Fortus 450mc 3D printers in 2017 to help accelerate the development of the XB-1 through tooling, prototypes and test benches, 3D printing over 200 parts in the process. Image via Stratasys.ģD printing speeds towards commercial supersonic travelįounded in 2014, Boom Supersonic aims to create the fastest commercial airliner using supersonic travel, and “make the world dramatically more accessible.” Its XB-1 aircraft is a demonstrator for developing mainstream supersonic travel, acting as a subscale prototype for Overture, the company’s Mach-2.2 commercial airliner.

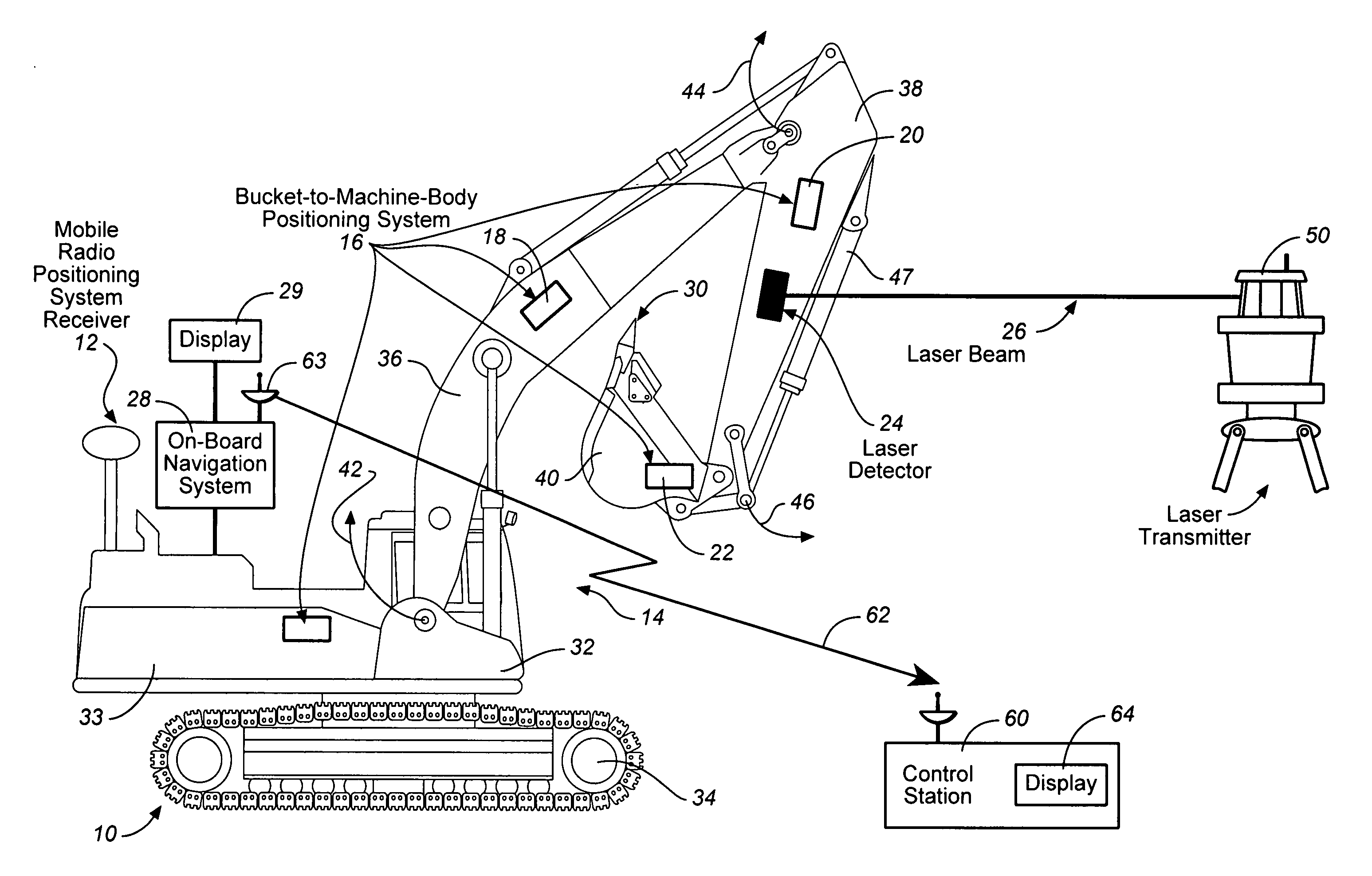

“Stratasys’ standing as a global leader in 3D printed aerospace applications made them an ideal partner for Boom, and we’re excited to extend this partnership long-term.” Composite part tooling developed using Stratasys 3D printing for the Boom Supersonic XB-1 aircraft. “By being able to print critical parts and components on site rather than purchasing them from a supplier, we can create custom parts, increase our speed from engineering to manufacturing, and focus on building the aircraft and fulfilling our vision,” explained Mike Jagemann, Head of XB-1 Production at Boom.

Now, under the extended long-term agreement, Boom Supersonic will continue to use Stratasys 3D printing to develop the XB-1 prototype as well as future commercial aircraft by using the AIS package. Their initial partnership began in 2017, when both companies agreed to leverage Stratasys’ F370 and Fortus 450mc 3D printers to support the development of Boom Supersonic’s demonstrator XB-1 aircraft. Under the agreement, both companies aim to further accelerate the adoption of additive manufacturing for flight hardware by utilizing Stratasys’ Aircraft Interiors Solution (AIS) package alongside the F900 3D printer.

#BOOM 3D COMPONENT INSTALLATION UPDATE#

In time for the Paris Air Show 2019, leading 3D printer OEM Stratasys has announced an update to its partnership with Boom Supersonic, a Colorado-based aerospace company, by signing a seven-year partnership extension.

0 kommentar(er)

0 kommentar(er)